CZU e entsoeng ka tšepe

Mekhoa ea tlhahiso eaCold Thehile Karolo Tšepe?

Ts'ebetso ea tlhahiso ea liloala tse kolobisitsoeng ka serame haholo-holo li laola ho lokisoa ha li-billet, ho kha, ho phutholla ho batang, ho kolobisoa le ho qeta.

Tokisetso e se nang letho e hloka sebopeho sa lik'hemik'hale, bophara le sekala sa botenya (phapang ea lintlha tse tharo le phapang e tšoanang ea line), 'me sekoba sa sekele se lokela ho finyella litlhoko,' me bokaholimo bo lokela ho ba boreleli le ho se na mapetsong, mameno, delamination, pores, non- metallic inclusions, joalo-joalo.

Litšepe li lokela ho otlolloa le ho tšeloa butt pele li khethoa bakeng sa ho khetha ho latellana.Morero o ka sehloohong oa pickling ke ho tlosa sekala sa iron oxide.Nakong ea ts'ebetso ea pickling, mahloriso le mocheso oa tharollo ea acid le lihlahisoa tsa letsoai la ferrous ka har'a tharollo ea acid li lokela ho laoloa.

E le ho laola botenya le sebopeho sa poleiti, ho fokotseha, lebelo, tsitsipano le sebopeho sa moqolo li lokela ho fetoloa.Botenya bo laoloa haholo ke AGC, 'me sebopeho sa poleiti se laoloa haholo ke ho lokisa boemo ba moqolo (moqhaka oa moqhaka le mokhoa oa puseletso ea moqhaka), joalo ka HC, CVC, jj.

Annealing e arotsoe ka bohareng annealing le finish annealing.Center annealing ke ho felisa ho thatafala ha mosebetsi, 'me annealing ea sehlahisoa ke ho fumana sebopeho le ts'ebetso e hlokahalang.Libōpi tse annealing li kenyelletsa libopi tse hlahlamanang le liopi tsa ho futhumatsa tsa mofuta oa tšepe.Ts'ebetso ea ho koala sebōpi sa mofuta oa tšepe e lokela ho laola karolo ea khase e sireletsang ka sebōping, nako ea ho futhumatsa le nako ea ho pholile;ts'ebetso ea ho koala sebōpi se latellanang se lokela ho laola mocheso, lebelo, nako le sepakapaka ho ea ka lekhalo la annealing.Laola tsitsipano ea hlobo ka seboping ho netefatsa sebopeho sa poleiti, le ho laola moqhaka oa sebopi ho qoba ho kheloha ha hlobo.

Ho qeta ho kenyelletsa ho batalla, ho itšeha, ho tlotsa oli le ho paka.Ho batalla ho ka ntlafatsa sebopeho sa poleiti, ho hloekisa bokaholimo le ho fumana mesebetsi e hlokahalang.Mokhoa oa ho batalla o lokela ho laola ho lelefatsa ha lesela, 'me ho kuta ho lokela ho laola boholo le boleng ba bokaholimo, oli e lokela ho ba junifomo,' me sephutheloana se lokela ho finyella litlhoko tse boletsoeng, tse loketseng ho boloka, ho tsamaisa le ho fana ka thepa.

| NO. | Boholo | Botenya | Mofuta | Bokaholimo Kalafo | ||

| mm | Intshi | Botenya | Lekhalo | |||

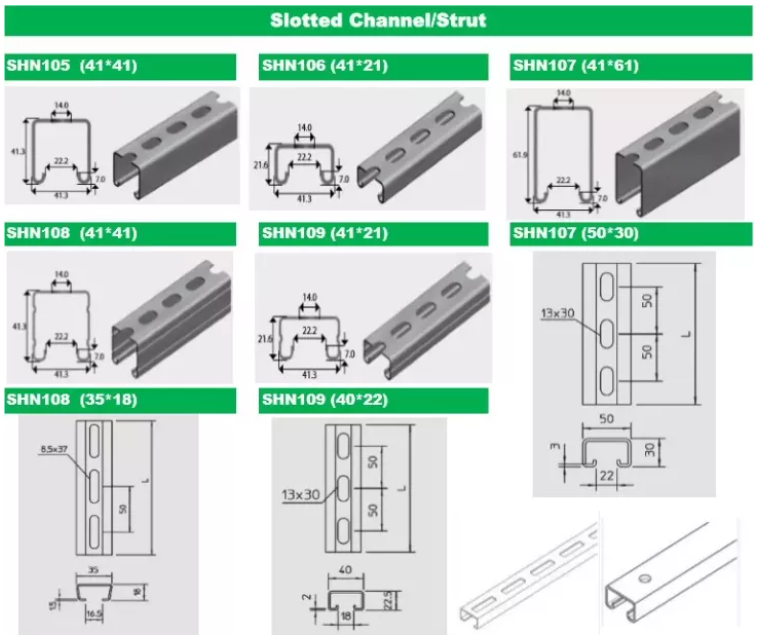

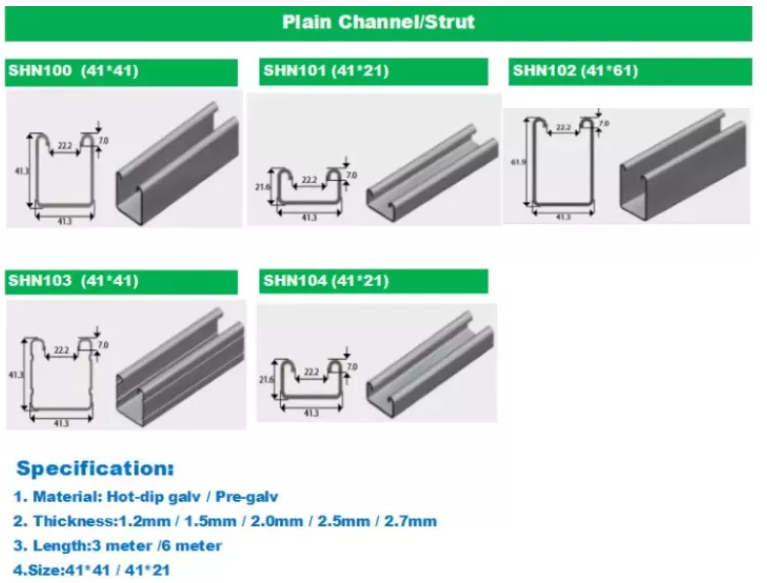

| A | 21*10 | 13/16*13/32" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

| B | 21*21 | 13/16*13/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

| C | 41*21 | 1-5/8*13/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

| D | 41*22 | 1-5/8*7/8" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

| E | 41*25 | 1-5/8*1" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

| F | 41*41 | 1-5/8*1-5/8" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

| G | 41*62 | 1-5/8*27/16" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

| H | 41*82 | 1-5/8*3-1/4" | 1.0,1.5,2.0,2.5,2.75,3.0 | 19,16,14,12 | E butsoitseng, E Tiileng | HDG, PG, PC |

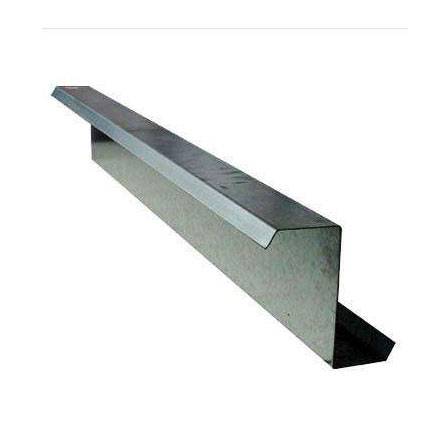

Tsohleserame se entsoeng ka tšepe c profileli entsoe ka mochini o iketsetsang mochini oa C-steel make-up, oo ho latela boholo ba tšepe ea C, o ka phethelang ts'ebetso ea ho theha C-steel.

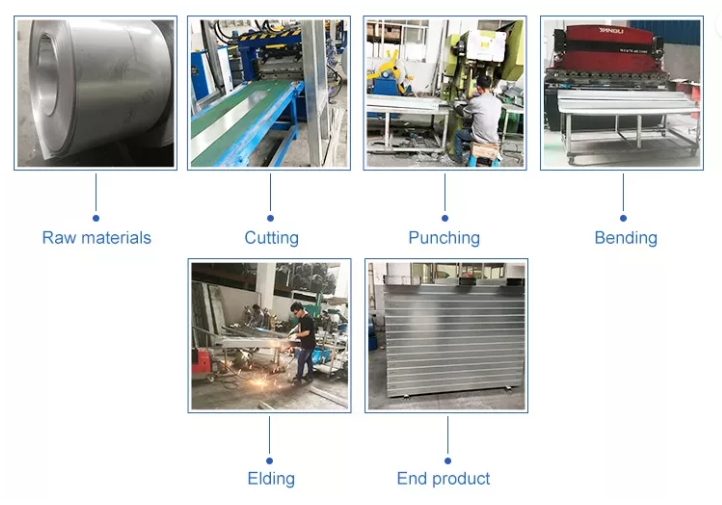

Feeding-Flattening-Forming-Sizing-Aigning-Length Measurement-Punching Round Hole for Tie-bar -Punching Oval Connection Hole-Molding Cutting-off